In the mid 1940s, sadhaks of Sri Aurobindo Ashram prepared handmade paper on a very small scale from waste material as a creative and useful work. In 1959 larger-scale papermaking equipment was installed in a coconut garden – including a beater, lifting vats, and a calendaring machine. The coconut garden is the location of the factory today, in the heart of Pondicherry.

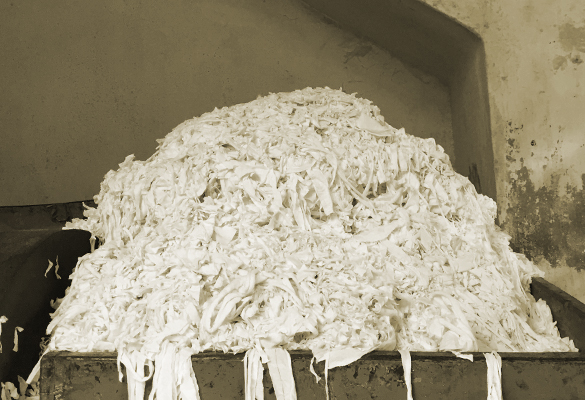

Off-cuts of white cotton rag are the main raw material in our handmade paper, sourced from the textile industry in Tiruppur, Tamil Nadu – waste which would otherwise be sent to landfill.

These off-cuts are sorted by hand before being cut into finer pieces through a cutting machine. The long, fine fibres of cotton make for strong and crisp paper which can last for centuries.

The cut rags enter our Hollander beaters along with water. The action of the beater macerates the rag, opening up the fine cotton fibres, known as fibrilation.

The skill and experience of the beater operator ensures the pulp is beaten to the right fineness. The finished pulp is then pumped to the lifting vats to be lifted into sheets.

Water is intrisic to papermaking. Ours comes from a well in the factory and is used sparingly. The used water is then treated on site and used to water our gardens, including the coconut trees.

With beaten the pulp ready, measured amounts are poured over the mould and deckle in the lifting vat to form each individual sheet.

Each sheet is hand-lifted with the skill of the lifter's technique in raising the mould out of the water with the right shake to form the sheet. Once on the mould, the sheet is couched on a felt blanket and then pressed, peeled, and hung in our drying room at the top of our factory, amongst the coastal breeze.

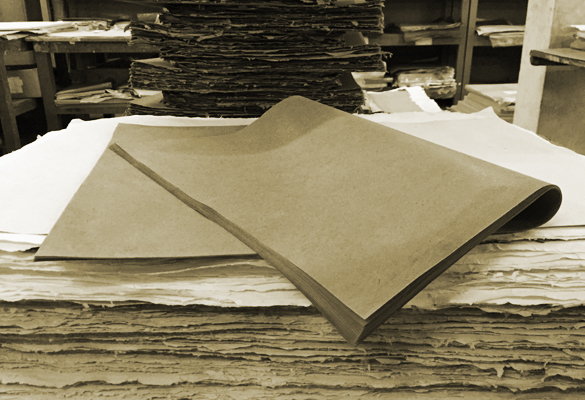

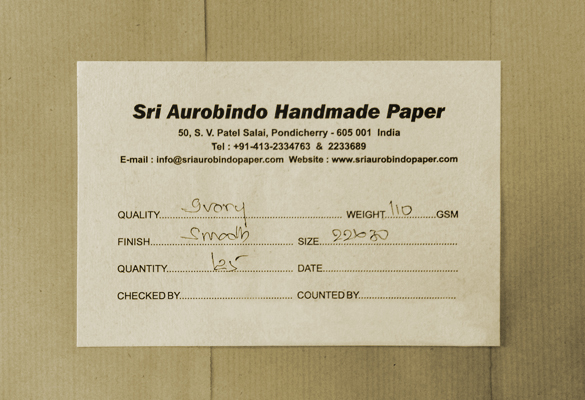

Once dry, each sheet is sorted and cleaned, before being calendared – a process of smoothening each sheet to achieve a desired finish.

Each sheet is individually placed in between stainless steel plates to be smoothened through the calendaring machine.

After calendaring, each sheet is individually reinspected.

Dry, smooth, sorted, and cut, the paper is ready for one of many possiblities – marbling, screen printing, stationery, or sold as is.

Natural, handmade, and filled with the consciousness of the Sri Aurobindo Ashram, our paper is used worldwide for archival storage, stationery and art.

In works, aspiration towards Perfection is true spirituality